ProductPRODUCT

Featured products

Contact Us

- ABB

- SDCS-CON-3

- Control Board

- Sweden

- 215 mm × 150 mm × 35 mm

- 0.5kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 143

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Introduction

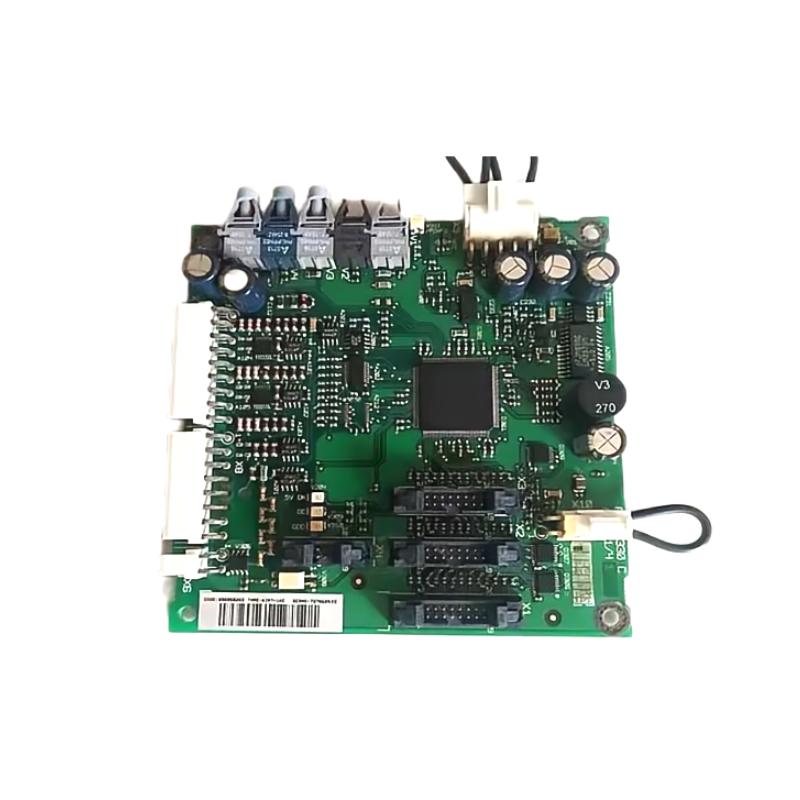

The SDCS‑CON‑3 is a high‑performance control and interface board designed for ABB’s DCS 600 / DCS 800 drive control system series. It serves as a central logic, communication & I/O management module within the drive rack, coordinating the interaction between control electronics, I/O modules, communication links and power converters.

Specifically, the SDCS‑CON‑3 acts as an advanced generation control board, offering improved processing speed, enhanced diagnostics, and upgraded I/O flexibility compared to earlier control modules. It manages analog and digital signals, monitors system health, and facilitates bus communication between modules and supervisory systems. The form‑factor is optimized for control‑cabinet installation, allowing compact layouts and simplified maintenance.

In industrial automation settings such as metallurgical plants, pulp & paper lines, mining conveyors, or marine / offshore drive systems, the SDCS‑CON‑3 provides the robust, reliable control backbone necessary for continuous, heavy‑duty operations.

Technical Parameters

| Parameter | Description |

|---|---|

| Model | SDCS‑CON‑3 |

| Brand | ABB |

| Series | DCS 600 / DCS 800 Drive Control Modules |

| Function | Control logic & interface board – I/O, communication & diagnostics |

| Input Voltage | 24 V DC nominal (logic/control supply) |

| Signal Types | Analog + digital I/O channels |

| Communication Interface | Internal bus, serial/fieldbus links |

| Processor Type | Embedded microcontroller with real‑time logic |

| Operating Temperature | 0 °C to +55 °C |

| Storage Temperature | ‑25 °C to +70 °C |

| Humidity Range | 5 %–95 % non‑condensing |

| Mounting Type | Plug‑in module (rack‑mounted inside control cabinet) |

| Protection Class | IP20 |

| Dimensions (L×W×H) | approx. 215 mm × 150 mm × 35 mm |

| Weight | approx. 0.50 kg |

| Cooling Method | Natural air convection |

| Typical Use | Central control board in DCS drive systems |

Product Application

The SDCS‑CON‑3 module finds its place wherever robust, real‑time control, monitoring and communication of complex drive systems are required. Typical application scenarios include:

-

Integration into ABB DCS 600 / DCS 800 DC drive systems as the main logic board, coordinating converter, measurement and communication modules.

-

Heavy‑duty industrial motor control applications: steel mills, rolling mills, large conveyors, mining operations, continuous process industries.

-

Pulp & paper production lines where synchronized drive sections, high uptime and accurate I/O handling are critical.

-

Marine and offshore propulsion or auxiliary drive systems where space is at a premium and reliability is vital.

-

Retrofit or modernization projects of legacy DCS drive systems — upgrading control modules to newer boards while retaining interface compatibility.

-

Energy & utility installations where drive modules connect to supervisory control/SCADA systems and I/O networks, requiring high‑level diagnostics and communication.

In each of these applications the SDCS‑CON‑3 provides the central control intelligence, enabling streamlined I/O orchestration, communication integrity, fault diagnostics, and system scalability.

Product Advantages

-

High Processing Performance – Faster logic, improved response, and higher throughput compared to legacy control modules.

-

Robust Industrial Design – Engineered for continuous operation in harsh environments, including temperature, humidity and electrical stress.

-

Modular & Plug‑in Architecture – Simplifies installation, upgrade and maintenance, reducing system downtime.

-

Comprehensive I/O and Communication – Supports a diverse range of analog/digital I/O and internal/external communications, enabling flexible automation architectures.

-

Enhanced Diagnostics & Monitoring – Supplies system health information, fault status and data logs to support preventive maintenance and uptime optimisation.

-

Compact & Lightweight – Saves space in control racks, promoting efficient layout and easier service access.

-

Seamless Integration – Compatible with the broader ABB DCS modular ecosystem, supporting system expansion and interface continuity.

-

Longevity & Low Maintenance – Designed for long service life, fewer replacements and lower total cost of ownership.

Brand Overview

Brand: ABB

ABB is a leading global provider of automation, drive and control technologies. The company’s drive control modules serve heavy‑industry, manufacturing, utilities, marine, mining and process markets. The SDCS‑CON‑3 is part of ABB’s advanced drive control component line, reflecting the brand’s commitment to reliability, innovation and system integration.

Product Series

Series Name: DCS 600 / DCS 800 Drive Control Module Series

This series comprises modular components such as control boards (CON series), measurement boards (AMC series), communication boards (COM series), bus adapter boards (BAB series), power supply modules (POW series) and I/O boards (IOB series). Each board fulfills a specific role and integrates within a standard back‑plane rack design. The SDCS‑CON‑3 belongs to the “CON” segment (control logic/interface) and is the advanced iteration of earlier CON boards.

Related or Same‑Series Models (5 Recommended)

| Model | Description | Voltage/System | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| SDCS‑CON‑2B | Predecessor control & interface board | 24 V DC nominal | ~215×150×35 | ~0.49 |

| SDCS‑CON‑2A | Earlier control module variant | 24 V DC nominal | ~215×150×35 | ~0.41 |

| SDCS‑AC‑CON‑2 | AC converter interface & control board | 24 V DC nominal | ~210×150×35 | ~0.45 |

| SDCS‑AMC‑DC‑2 | Analog/Digital measurement & control board | 24 V DC nominal | ~215×150×35 | ~0.47 |

| SDCS‑BAB‑F01 | Bus adapter communication interface board | 24 V DC nominal | ~215×155×35 | ~0.46 |

Popular ABB Models (5 Recommended)

| Model | Product Type | Application Area | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| ACS880‑01‑07A6‑3 | AC Drive | Process automation, heavy machinery | 390×260×160 | ~5.2 |

| DCS800‑S01‑0045‑05 | DC Drive Controller | Heavy‑duty industrial drive systems | 480×300×200 | ~7.6 |

| ACS580‑01‑025A‑4 | Variable Frequency Drive | HVAC, pumps, conveyors | 380×250×180 | ~5.8 |

| ACS355‑03E‑04A7‑2 | Compact AC Drive | Light automation, OEM machinery | 200×90×180 | ~2.5 |

| ACS150‑03E‑07A5‑4 | Micro AC Drive | Small motors, fans, OEM applications | 180×75×160 | ~2.1 |

FAQ (Frequently Asked Questions)

Q1: What is the main role of the SDCS‑CON‑3 module?

A1: It functions as the central control logic board within the DCS modular rack, managing I/O, communication, diagnostics and integration between drive control modules.

Q2: Which drive systems is the module compatible with?

A2: It is designed for use in the DCS 600 / DCS 800 drive control system architecture.

Q3: What is the supply voltage for the board?

A3: The module operates on a nominal 24 V DC control power supply.

Q4: Does it support both analog and digital I/O channels?

A4: Yes — it supports multiple analog and digital input/output channels and handles internal communication links.

Q5: Can this board be installed easily during retrofits?

A5: Yes — its plug‑in modular design simplifies installation, replacement and system upgrades.

Q6: What diagnostics capabilities are included?

A6: The board includes monitoring for fault detection, I/O status, communication errors and self‑tests to support maintenance.

Q7: Which industries commonly use this module?

A7: It is widely used in steel, mining, pulp & paper, marine/offshore, power generation and process automation industries.

Q8: What environmental conditions can the module operate under?

A8: It supports 0 °C to +55 °C operating temperature and 5 %–95 % relative humidity non‑condensing.

Q9: What is the expected lifespan of the module?

A9: With proper installation and environment, the module typically offers over ten years of reliable service.

Q10: What are the advantages of upgrading to SDCS‑CON‑3 over earlier control modules?

A10: Key advantages include improved processing speed, enhanced diagnostics, greater I/O and communication flexibility, and better system integration capabilities — all contributing to higher uptime and lower maintenance.