ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 330850-90-00

- Proximitor Sensor

- USA

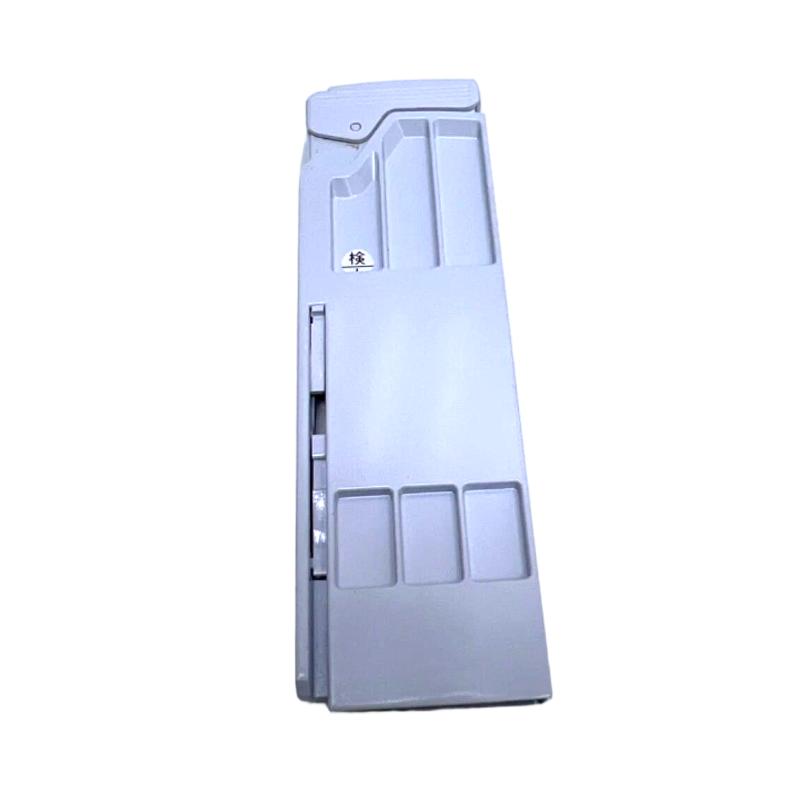

- 105 mm (L) × 75 mm (W) × 25 mm (H)

- 0.255kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 170

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

1. Product Overview — Bently Nevada 330850‑90‑00

Introduction

The Bently Nevada 330850‑90‑00 is a member of the 3300 XL 25 mm Proximitor sensor family (non‑contact displacement / proximity sensor). Its principal role is to measure radial displacement (gap), vibration, or shaft movement in rotating machinery by converting signals from a proximity probe and extension cable into a usable electrical output.

The “90” in its part number denotes a 9.0‑metre total system length (probe + cable + sensor). The “00” suffix indicates it is a no‑approval model (i.e. without special agency certifications).

Because of its extended length, it is suited for installations where the sensing probe may be located further from the instrumentation panel or where access is constrained.

This model is used in power plants, petrochemical plants, process facilities, rotating equipment diagnostic setups, etc.

2. Technical Specifications — 330850‑90‑00

Below is a consolidated table of known or credible specifications for 330850‑90‑00. Some values are from public listings and inference based on similar models, so for critical engineering use you should confirm via the official datasheet.

| Parameter | Specification / Remark |

|---|---|

| Model | 330850‑90‑00 |

| Series / Type | 3300 XL 25 mm Proximitor Sensor (non‑contact displacement) |

| Total System Length | 9.0 meters (probe + extension cable + proximitor) |

| Mounting / Installation Style | Panel mount style (for “90” version) — typically the proximitor sensor is panel-mounted |

| Approval / Certification | “00” → no special approvals / agency certifications |

| Measurement / Linear Range | 0 to 12.7 mm full scale, linear from ~2 to 12.7 mm (80 to 500 mils) |

| Output Sensitivity | –200 mV/mil ≈ –7.87 mV/µm |

| Frequency Response | 0 to 10 kHz |

| Operating Temperature (Probe) | –35 °C to +177 °C |

| Operating Temperature (Cable / Sensor) | –51 °C to +177 °C |

| Storage Temperature | –51 °C to +100 °C |

| Pressure Tolerance | Up to 10,000 psi (≈ 68,947 kPa) |

| Probe Thread / Interface | 1.0‑inch UNF‑20 thread for probe interface |

| Material / Enclosure | Aluminum alloy (A380 or similar) housing for the proximitor sensor |

| RFI / EMI Immunity | Improved immunity to high-frequency interference (for CE marking / industrial use) |

| SpringLoc® Terminals | Yes — tool-free wiring and robust connections |

| Dimensions (estimated) | ≈ 105 mm (L) × 75 mm (W) × 25 mm (H) (typical for the series) |

| Weight | Approx. 0.255 kg (sensor module only) |

| Shipping / Packed Weight | ~2.0 kg (public listing for shipping weight) |

Notes / Clarifications:

-

The listing from Teknihaus states: “Mounting Option: 9.0 m system length, panel mount, no approvals, shipping weight: 2 kg”

-

Other listings confirm the “00” suffix means “no approvals” and that the sensor is panel mount for the “90” version

-

Public listings also claim measurement range to 12.7 mm, frequency bandwidth to 10 kHz, pressure rating 10,000 psi, and sensitivity –200 mV/mil

-

Notice the probe’s temperature rating is very high (–35 to +177 °C) in some listings, likely indicating a high-temperature probe compatibility.

3. Applications

The 330850‑90‑00 is suitable in scenarios where the sensing probe must be placed further away from the monitoring electronics due to layout constraints. Typical applications include:

-

Turbine generator shaft displacement / vibration measurement

-

Large motors, compressors, pumps in process plants

-

Long extension distances in control rooms or remote panels

-

Retrofitting older 7200 / DE proximity systems with modern 3300 XL series

-

Vibration analysis, trend monitoring, and protective alarm systems

-

Condition monitoring in petrochemical, refining, power generation facilities

Because of its 9 m length, it allows flexibility in panel placement without needing intermediate signal repeaters, which is beneficial in complex installations.

4. Advantages & Key Features

Here are the key benefits and design highlights of the 330850‑90‑00:

-

Extended reach: The 9.0 m system length supports installations where the probe is remote from the control instrumentation.

-

Non-contact measurement: No physical contact with shaft, avoiding wear and friction effects.

-

High dynamic response: Up to 10 kHz bandwidth captures fast vibration events.

-

Robust against interference: Designed with good EMI/RFI suppression, suitable for harsh industrial environments.

-

Proven compatibility: Fully compatible with the 3300 XL 25 mm family of probes, extension cables, and monitoring modules.

-

SpringLoc wiring: Simplifies field wiring and helps maintain strong electrical connections without special tools.

-

High-temperature probe compatibility: Some data suggests support of high probe temperatures (up to +177 °C) enabling use in hot zones.

-

Flexible mounting: Panel-mount proximitor module allows easier integration into existing cabinets.

-

Reliable brand lineage: Backed by a strong track record of reliability in rotating machinery monitoring systems.

5. Related / Same‑Series or Associated Models (5 Suggestions)

Here are 5 models in the 330850 / 3300 XL family or close variants. The first column is bolded as requested. Some parameters are taken from public listings or inferred by analogy.

| Model | System Length / Mounting | Approval / Variant | Approx. Weight / Size | Highlights / Differences |

|---|---|---|---|---|

| 330850‑50‑00 | 5.0 m, panel mount | No approval (“00”) | ~0.10 kg (module) | Short-length version for tight panels |

| 330850‑51‑00 | 5.0 m, DIN rail mount | No approval (“00”) | ~0.255 kg | DIN-rail placement variant |

| 330850‑90‑05 | 9.0 m, panel mount | Multi-approval (“05”) | ~0.246 kg module | Similar length but with approvals |

| 330850‑91‑05 | 9.0 m, DIN rail mount | Multi-approval (“05”) | ~0.50 kg (est.) | DIN-rail form of extended-length approved version |

| 330850‑50‑05 | 5.0 m, panel mount | Multi-approval (“05”) | ~0.10 kg (module) | Short length with approvals |

These variants allow selection based on length requirement, mounting style (panel vs DIN), and certification requirements.

6. Other Popular Models from the Same Brand (5 Examples)

To provide context in the broader product portfolio, here are five popular or commonly used models from the same brand (Bently Nevada), often co‑used or seen in system deployments:

| Model | Type / Function | Key Attributes | Usage / Role |

|---|---|---|---|

| 330105‑02‑12‑05‑02‑00 | Proximitor Probe / Module | Configurable proximity probe | Interface to probe in 3300 systems |

| 3500 / 05‑01‑01‑00‑00 | Rack-mounted monitoring module | Multi-channel, slot-based design | Central vibration monitoring rack |

| 9200‑03‑05‑10‑00 | Intelligent / Smart monitoring sensor | High-speed / digital output | Asset diagnostics, IIoT integration |

| 176449‑03 | Signal conditioning / interface card | Filtering, conversion, interface | In system processing / I/O interfaces |

| 330500 Velomitor | Velocity vibration transducer | Outputs velocity (as opposed to displacement) | Complementary vibration measurements |

7. 10 FAQs (Q / A) for 330850‑90‑00

Q1: Why choose the 330850‑90‑00 instead of a 5.0 m version?

A1: Because in many installations, the probe may be physically remote from instrumentation cabinets or panels. The 9.0 m length accommodates longer cable runs without needing signal extenders or repeaters, simplifying installation.

Q2: Does the “00” suffix limit use in industrial / certified zones?

A2: Yes, the “00” suffix indicates no special approvals (e.g. no ATEX, IECEx, or other agency certifications). It is suited for non-hazardous area usage. If you require certified models, choose a “05” or approved suffix.

Q3: How strict is the power supply requirement?

A3: Very strict. The proximitor sensor must be provided by a compatible monitoring unit or power source. Incorrect voltage or polarity may degrade linearity or damage the unit.

Q4: Can the probe handle very high temperatures?

A4: Yes, some sources list the probe operating up to +177 °C, which makes it suitable for certain high-temperature zones when appropriately selected.

Q5: What is the linear measurement range vs full scale?

A5: The full scale is ~12.7 mm, but linearity is maintained roughly from 2 mm to 12.7 mm. Outside that, the measurement may become non-linear or saturated.

Q6: How does EMI / RFI affect measurement?

A6: This model is designed with enhanced immunity to electromagnetic interference and radio-frequency noise, helping maintain signal integrity even in electrically noisy environments.

Q7: What is the physical weight and dimensions?

A7: The proximitor sensor module weighs about 0.255 kg. Dimensions approximate 105×75×25 mm. The shipping / package weight is around 2.0 kg.

Q8: What maintenance or calibration requirements does it have?

A8: Periodic checks of zero and span, verifying probe alignment and cable integrity, ensuring terminal connections are clean and tight, and verifying output stability over temperature cycles.

Q9: Can I reuse old extension cables from 7200 systems?

A9: It is not recommended unless cable parameters (capacitance, impedance, shielding) match. The 3300 XL system expects cables optimized for its signal paths. Mismatched cables may degrade performance.

Q10: What is the expected service life?

A10: Under normal environmental conditions and correct electrical installation, these sensors often last 5–10+ years. Life is influenced by vibration, shock, thermal cycles, and electrical stresses.