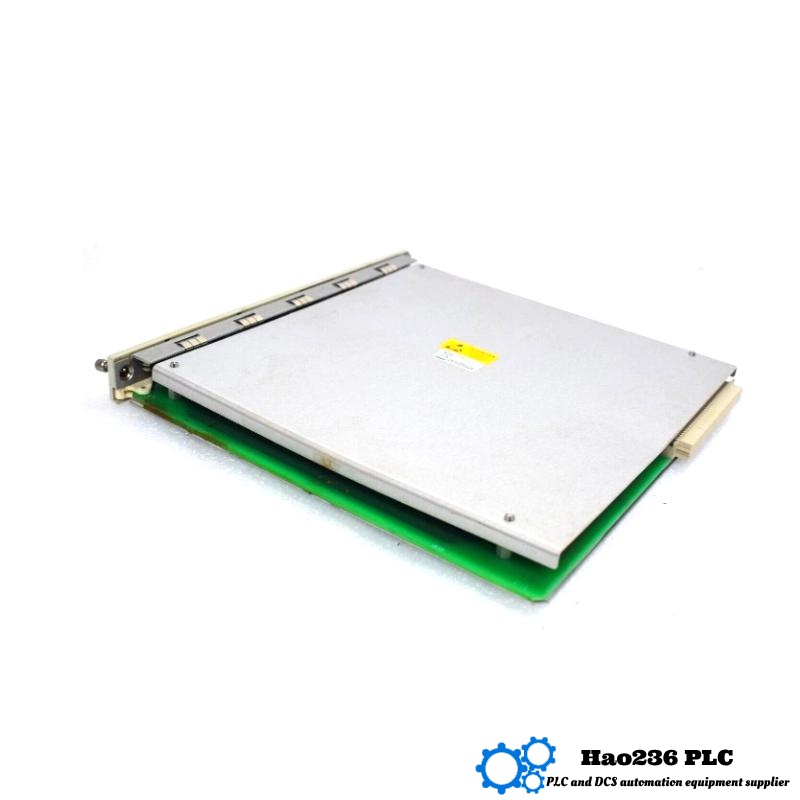

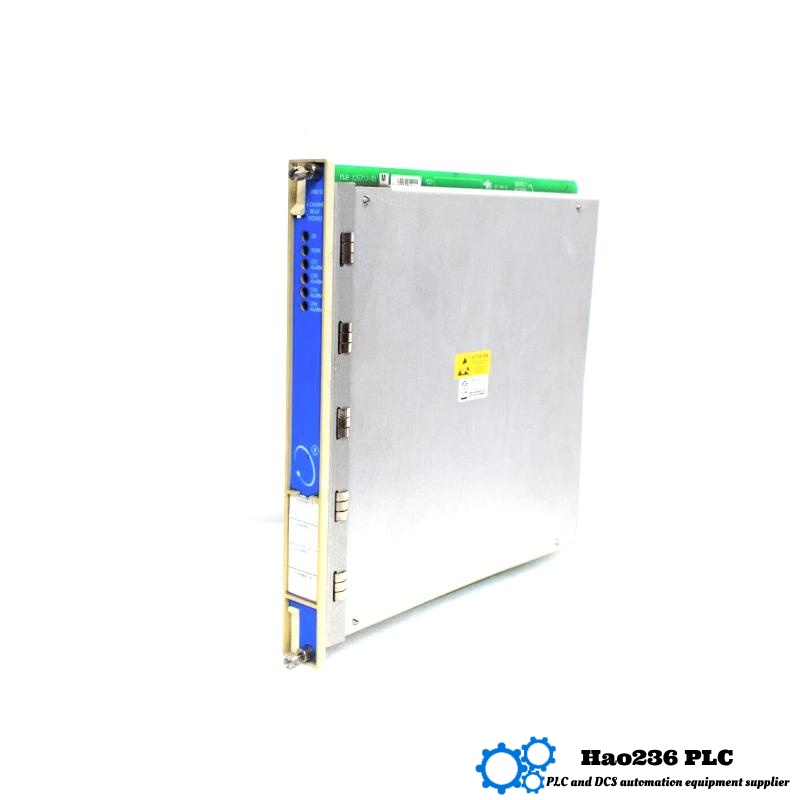

Product Overview: Bently Nevada 3500/32 125720-02 + 125712-01

Product Introduction:

The Bently Nevada 3500/32 125720-02 + 125712-01 is a part of the 3500 Series vibration and machine condition monitoring systems. This advanced monitoring solution is specifically designed to ensure the health and performance of rotating machinery such as turbines, compressors, motors, pumps, and other critical mechanical assets. By continuously collecting real-time data on parameters like vibration, displacement, and position, it helps to detect early signs of equipment degradation, providing operators with the information needed to take proactive maintenance actions and avoid unexpected downtime.

The 3500/32 system is widely used across industries like power generation, oil and gas, chemical processing, manufacturing, and HVAC. Its real-time monitoring and advanced diagnostic capabilities help to extend the lifespan of machinery and reduce the risk of catastrophic failures.

Product Features:

-

Real-time Monitoring: Continuously tracks key performance parameters such as vibration and displacement, giving operators up-to-date information on the health of critical machinery.

-

Advanced Diagnostics: Features like trend analysis and early fault detection help identify potential issues before they cause significant damage or downtime.

-

Scalability: Easily scalable to monitor additional machines, making it a flexible solution for both small and large-scale installations.

-

Ease of Use: The 3500/32 comes with a user-friendly interface that simplifies system setup, monitoring, and diagnostics.

-

Durable Design: Designed to withstand tough industrial environments, with an IP65-rated enclosure, ensuring protection against dust, water, and temperature extremes.

-

Multiple Communication Options: Supports Modbus, Profibus, and Ethernet, facilitating seamless integration into existing industrial control systems.

Product Specifications:

| Specification |

Details |

| Model Number |

3500/32 125720-02 + 125712-01 |

| Type |

Vibration, Displacement, and Position Monitoring System |

| Dimensions (L x W x H) |

280 mm x 170 mm x 60 mm |

| Weight |

1.6 kg |

| Input Voltage |

24V DC |

| Measurement Range |

0 – 1000 Hz |

| Operating Temperature |

-20°C to 60°C |

| Environmental Protection |

NEMA 4X / IP65 |

| Mounting Type |

Panel or DIN Rail |

| Communication Protocols |

Modbus, Profibus, Ethernet |

Product Application:

The 3500/32 system is used for monitoring the condition of critical machinery in the following sectors:

-

Power Generation: Monitoring turbines, generators, and motors to ensure the smooth and efficient operation of power plants.

-

Oil & Gas: Essential for protecting rotating equipment such as compressors, pumps, and motors in refineries, offshore rigs, and processing plants.

-

Chemical Processing: Offers real-time diagnostics of reactors, mixers, and pumps in chemical manufacturing plants to prevent operational disruptions.

-

Manufacturing: Enables predictive maintenance for critical production machinery such as motors, fans, and conveyors to minimize downtime and improve operational efficiency.

-

HVAC: Ideal for monitoring large HVAC systems in commercial and industrial buildings, ensuring consistent airflow and temperature control.

Product Advantages:

-

Proactive Maintenance: The 3500/32 enables predictive maintenance by detecting early warning signs of equipment failure, such as misalignment, imbalance, and bearing wear.

-

Reduced Downtime: By providing real-time diagnostic information, the system helps avoid unexpected failures and allows operators to plan repairs before they cause major disruptions.

-

Increased Equipment Lifespan: Early detection of potential problems helps extend the lifespan of critical machinery, reducing the need for costly replacements.

-

Improved Reliability: The 3500/32 enhances the reliability of rotating equipment, helping to keep operations running smoothly with fewer unexpected shutdowns.

-

Scalable Solution: The system can be expanded to monitor additional equipment, making it suitable for both small and large installations.

-

Rugged Construction: The NEMA 4X/IP65-rated enclosure provides protection against environmental factors such as dust, moisture, and temperature fluctuations, ensuring the system remains reliable even in harsh industrial environments.

-

Ease of Use: The intuitive interface and easy-to-install design reduce the complexity of setting up and operating the system, even for operators with minimal training.

Brand:

-

Brand: Bently Nevada

-

Brand Overview: Bently Nevada is a leading provider of machinery condition monitoring systems, offering innovative products designed to improve equipment reliability and reduce operational risks. Their systems are widely trusted in industries such as power generation, oil and gas, and manufacturing.

Series:

Recommended Products in the Same Series or Related Models

| Model Number |

Key Features |

Weight (kg) |

Dimensions (L x W x H) |

| 3500/40 |

Vibration and displacement monitoring for turbines |

1.5 |

280 mm x 170 mm x 60 mm |

| 3500/45 |

High-speed rotating equipment protection |

1.7 |

280 mm x 170 mm x 60 mm |

| 3500/53 |

Machinery protection for compressors and pumps |

1.6 |

275 mm x 165 mm x 58 mm |

| 3500/22 |

Vibration monitoring for motors and fans |

1.4 |

265 mm x 160 mm x 58 mm |

| 3500/77 |

Protection system for turbines and motors |

1.5 |

270 mm x 165 mm x 60 mm |

Recommended Popular Models from the Same Brand

| Model Number |

Key Features |

Weight (kg) |

Dimensions (L x W x H) |

| 3500/42 |

Vibration and displacement sensor for rotating machinery |

1.3 |

250 mm x 160 mm x 55 mm |

| 3500/53M |

Machinery protection for compressors and turbines |

1.4 |

275 mm x 160 mm x 60 mm |

| 3500/35 |

Diagnostic system for gas turbines |

1.5 |

280 mm x 170 mm x 60 mm |

| 3500/22M |

Monitoring and diagnostics for motors and pumps |

1.4 |

260 mm x 155 mm x 55 mm |

| 3500/90 |

High-speed rotating equipment protection |

1.6 |

275 mm x 165 mm x 58 mm |