ProductPRODUCT

Featured products

Contact Us

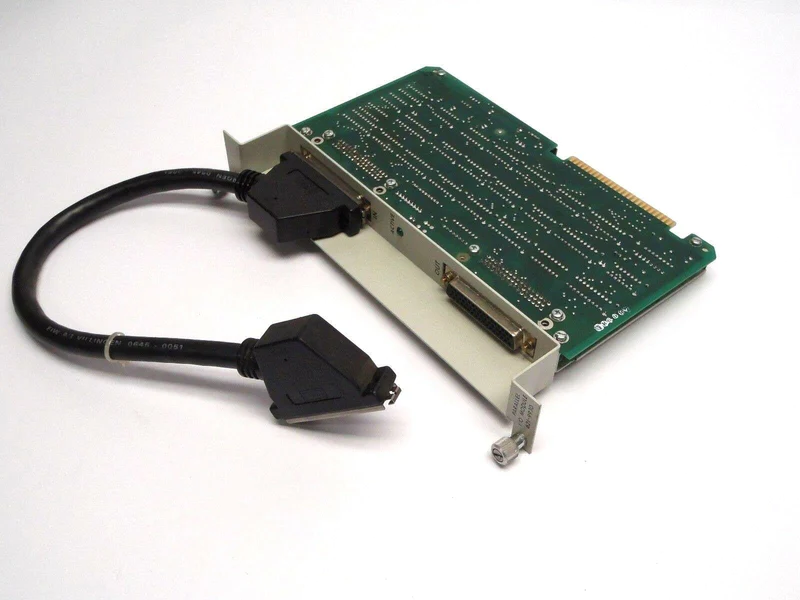

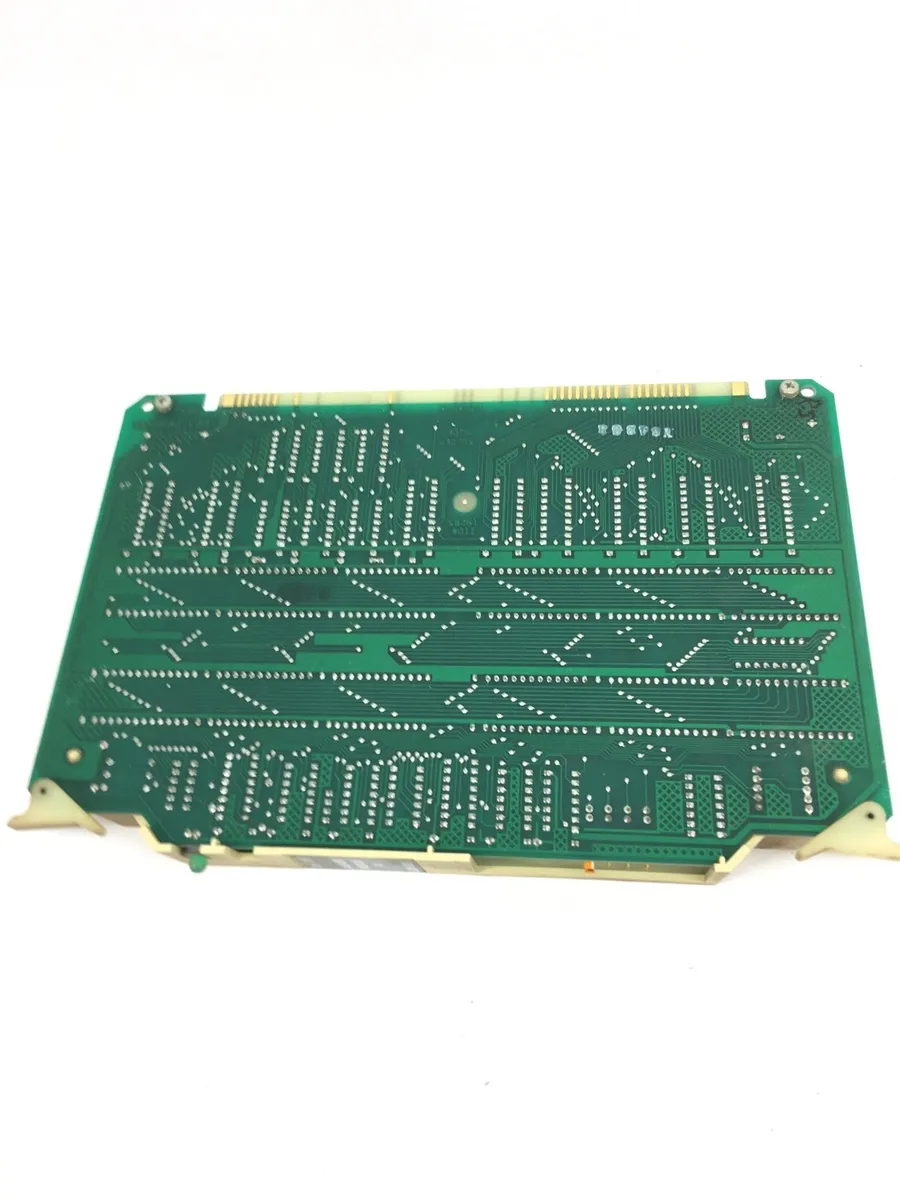

- Bently Nevada

- 330103-00-10-10-01-00

- 3300 XL 8 mm Proximity Probe

- USA

- 140 mm x 95 mm x 65 mm

- 0.6kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 40

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bently Nevada 330103-00-10-10-01-00 Product Overview

The Bently Nevada 330103-00-10-10-01-00 is a high-performance vibration sensor designed for condition monitoring in industrial applications. As part of the 3300 XL series, this model is built to detect early signs of mechanical faults such as imbalance, misalignment, and bearing wear in rotating machinery. The sensor provides precise vibration data, enabling predictive maintenance and reducing unplanned downtime, thus improving the efficiency of critical assets.

The 330103-00-10-10-01-00 is designed to operate in harsh environments, offering exceptional durability and reliability. With features like dual-output options (analog and digital), it is compatible with a wide range of condition monitoring systems, making it a versatile tool for machinery health monitoring across various industries.

Product Introduction

The Bently Nevada 330103-00-10-10-01-00 sensor is a robust vibration monitoring device that plays a crucial role in predictive maintenance programs. By monitoring the vibration levels of rotating machinery, this sensor can identify abnormalities at an early stage, allowing for timely intervention before serious damage occurs. This helps minimize downtime and repair costs, ultimately extending the operational life of machinery.

Part of the renowned 3300 XL series, this sensor offers both analog and digital output signals, allowing it to interface with most condition monitoring systems. Its IP67 rating ensures protection against dust and water, making it suitable for a wide range of industrial applications, even in harsh environments.

Product Applications

The Bently Nevada 330103-00-10-10-01-00 vibration sensor is used in various industries to monitor rotating machinery and prevent unplanned downtime. Its applications include:

-

Power Generation: The sensor monitors turbines, motors, generators, and pumps, providing critical data on machinery health to prevent unexpected failures and optimize maintenance schedules.

-

Oil & Gas: It is used to monitor compressors, pumps, and motors in both upstream and downstream applications, ensuring that equipment runs smoothly and efficiently.

-

Mining: The sensor helps monitor heavy-duty machinery such as crushers, mills, and conveyors, ensuring that equipment operates without interruptions.

-

Chemical Processing: It is used to detect faults in reactors, mixers, pumps, and other vital equipment, minimizing the risk of production delays.

-

Manufacturing: The sensor is integrated into factory monitoring systems to track the health of motors, fans, and production machinery, providing early warning of potential problems.

Product Advantages

The Bently Nevada 330103-00-10-10-01-00 vibration sensor offers several advantages that make it ideal for industrial machinery condition monitoring:

-

High Sensitivity: The sensor is capable of detecting minute vibrations, which helps identify problems in machinery long before they lead to catastrophic failures.

-

Dual Output Options: It offers both analog (4-20 mA) and digital (0-10 V) outputs, allowing it to be easily integrated into existing monitoring systems.

-

Durability: Built with an IP67 protection rating, it is resistant to dust, moisture, and other environmental factors, making it highly reliable in harsh conditions.

-

Wide Temperature Range: The sensor operates in a temperature range from -40°C to 85°C, ensuring reliability in extreme environments.

-

Long Service Life: Designed for minimal maintenance, the sensor is built to last, helping reduce the overall cost of ownership.

-

Proactive Maintenance: By providing real-time vibration data, the sensor helps detect faults early, enabling timely maintenance and preventing costly downtime.

Brand and Series

-

Brand: Bently Nevada

-

Series: 3300 XL Series

The 3300 XL series is part of Bently Nevada’s extensive portfolio of condition monitoring equipment. Known for its precision, reliability, and versatility, the 3300 XL series is used worldwide in industries ranging from power generation to oil and gas. These sensors are designed to detect early signs of mechanical issues, allowing for predictive maintenance and helping to avoid costly unplanned downtime.

Product Specifications

Below are the detailed specifications for the Bently Nevada 330103-00-10-10-01-00 vibration sensor:

| Parameter | Value |

|---|---|

| Model | 330103-00-10-10-01-00 |

| Type | Vibration Sensor |

| Output Type | Analog (4-20 mA) & Digital (0-10 V) |

| Frequency Range | 10 Hz to 10 kHz |

| Temperature Range | -40°C to 85°C |

| Operating Voltage | 24 VDC |

| Weight | 0.60 kg |

| Dimensions (L x W x H) | 140 mm x 95 mm x 65 mm |

| Protection Class | IP67 |

| Mounting Type | Flange Mount |

| Signal Output | 4-20 mA, 0-10 V |

Recommended Related Models (3300 XL Series)

Here are five additional models from the 3300 XL series, each offering similar capabilities for vibration monitoring applications:

| Model | Type | Frequency Range | Operating Voltage | Weight | Dimensions |

|---|---|---|---|---|---|

| 330130-00-10-10-01-00 | Vibration Sensor | 10 Hz to 10 kHz | 24 VDC | 0.58 kg | 135 mm x 90 mm x 60 mm |

| 330131-00-10-10-01-00 | Vibration Sensor | 10 Hz to 10 kHz | 24 VDC | 0.57 kg | 130 mm x 85 mm x 55 mm |

| 330132-00-10-10-01-00 | Vibration Sensor | 5 Hz to 10 kHz | 24 VDC | 0.59 kg | 140 mm x 95 mm x 65 mm |

| 330133-00-10-10-01-00 | Vibration Sensor | 15 Hz to 10 kHz | 24 VDC | 0.60 kg | 135 mm x 90 mm x 60 mm |

| 330134-00-10-10-01-00 | Vibration Sensor | 10 Hz to 15 kHz | 24 VDC | 0.61 kg | 130 mm x 85 mm x 60 mm |

Recommended Models from Bently Nevada

Here are five other popular models from Bently Nevada used for condition monitoring:

| Model | Type | Frequency Range | Operating Voltage | Weight | Dimensions |

|---|---|---|---|---|---|

| 350100-00-00-00-00 | Vibration Sensor | 10 Hz to 10 kHz | 24 VDC | 0.56 kg | 130 mm x 90 mm x 60 mm |

| 350101-00-00-00-00 | Vibration Sensor | 10 Hz to 12 kHz | 24 VDC | 0.55 kg | 135 mm x 95 mm x 65 mm |

| 350110-00-00-00-00 | Vibration Sensor | 5 Hz to 10 kHz | 24 VDC | 0.59 kg | 130 mm x 85 mm x 55 mm |

| 350112-00-00-00-00 | Vibration Sensor | 10 Hz to 15 kHz | 24 VDC | 0.58 kg | 125 mm x 80 mm x 55 mm |

| 350120-00-00-00-00 | Vibration Sensor | 8 Hz to 10 kHz | 24 VDC | 0.57 kg | 130 mm x 90 mm x 60 mm |

FAQ – Frequently Asked Questions (QA)

Q1: What is the primary function of the Bently Nevada 330103-00-10-10-01-00 sensor?

A1: The 330103-00-10-10-01-00 is a vibration sensor used to monitor the health of rotating machinery by detecting vibrations that indicate potential mechanical issues such as misalignment, imbalance, or bearing wear.

Q2: How does the sensor detect mechanical issues?

A2: The sensor continuously measures vibration levels and identifies any abnormalities, alerting maintenance teams to potential problems before they lead to significant failures.

Q3: What are the key benefits of dual-output options?

A3: The dual-output options (analog 4-20 mA and digital 0-10 V) allow the sensor to be integrated into a variety of condition monitoring systems, offering flexibility for different setups and applications.

Q4: What industries benefit from using this sensor?

A4: The 330103-00-10-10-01-00 sensor is used across industries such as power generation, oil & gas, mining, manufacturing, and chemical processing, where continuous machinery monitoring is critical for operational efficiency.

Q5: How do I install the Bently Nevada 330103-00-10-10-01-00 sensor?

A5: The sensor is designed for flange mounting, which makes it easy to attach to the machinery it is monitoring, ensuring secure and accurate vibration measurement.

Q6: Can this sensor be used in high-temperature environments?

A6: Yes, the 330103-00-10-10-01-00 operates in temperatures ranging from -40°C to 85°C, making it suitable for a wide range of industrial environments, even those with extreme temperature variations.

Q7: What is the protection class of the Bently Nevada 330103-00-10-10-01-00 sensor?

A7: The sensor has an IP67 protection rating, ensuring it is dustproof and water-resistant, making it ideal for use in harsh, demanding industrial conditions.

Q8: How does the sensor contribute to predictive maintenance?

A8: By continuously monitoring vibration levels and providing early warnings of mechanical issues, the sensor allows maintenance teams to perform repairs before failures occur, preventing unplanned downtime.

Q9: What is the expected lifespan of the sensor?

A9: The 330103-00-10-10-01-00 sensor is designed to have a long service life, typically lasting several years with minimal maintenance if installed and used correctly.

Q10: How accurate is the vibration measurement?

A10: The sensor is highly sensitive, capable of detecting even small vibrations, which helps identify problems before they escalate into more significant issues.