ProductPRODUCT

Featured products

Contact Us

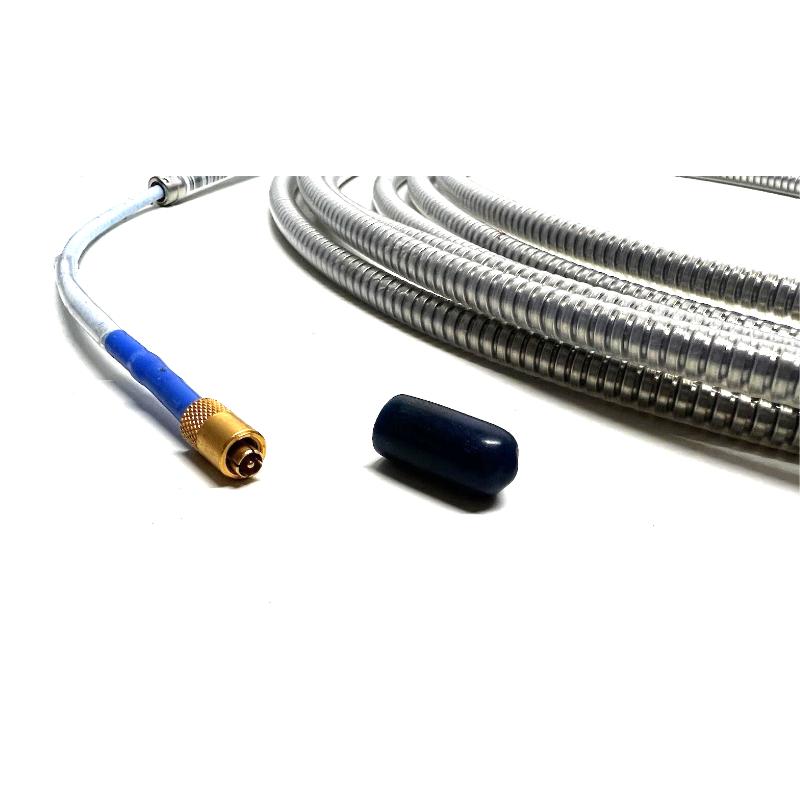

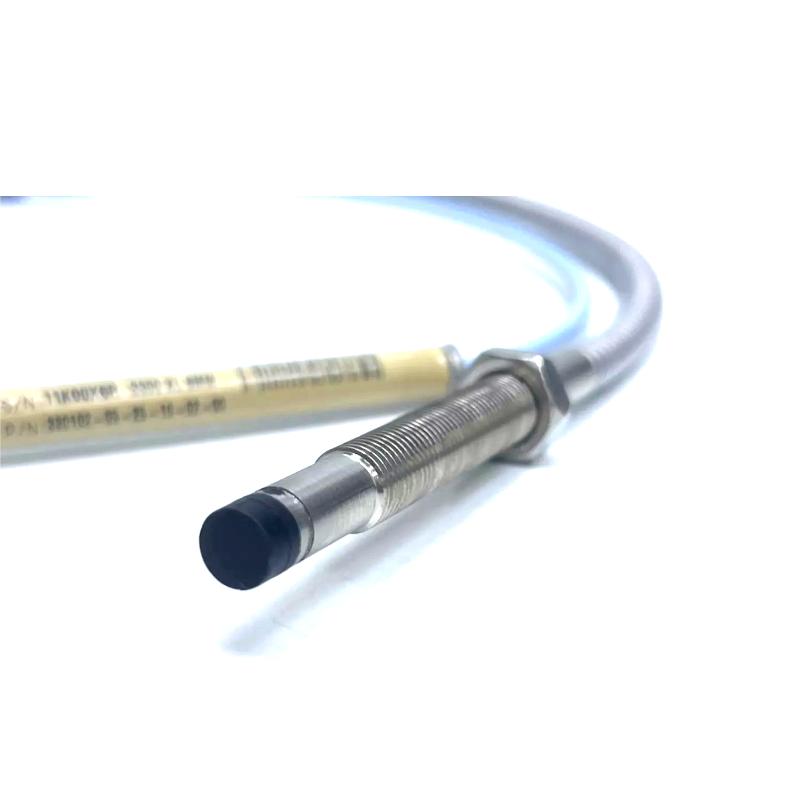

- Bently Nevada

- 330102-00-20-10-02-00

- 3300 XL 8 mm Proximity Probe

- USA

- 145 mm x 95 mm x 48 mm

- 0.56kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 27

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Bently Nevada 330102-00-20-10-02-00 Vibration Sensor Overview

Product Introduction

The Bently Nevada 330102-00-20-10-02-00 is a part of the renowned 3300 XL series, a high-performance vibration sensor designed for continuous machinery condition monitoring in industrial applications. This sensor provides early fault detection and is particularly useful in monitoring rotating machinery, such as motors, turbines, and compressors, to detect issues like misalignment, imbalance, and bearing failure. By using this sensor, operators can prevent costly downtime and extend the lifespan of critical machinery.

Applications

The 330102-00-20-10-02-00 sensor is commonly used in industries where critical machinery must be continuously monitored to ensure smooth and efficient operation. Some of its key applications include:

-

Power Generation: Continuous monitoring of turbines, generators, and other power generation equipment to prevent unexpected failures.

-

Oil & Gas: Detecting issues in pumps, compressors, and turbines in oil rigs and refineries.

-

Manufacturing: Monitoring motors, conveyors, and production lines to reduce downtime and improve productivity.

-

Mining: Used on crushers, mills, and other machinery to detect vibration anomalies and prevent unplanned maintenance.

-

HVAC Systems: Applied in monitoring fans, air handling units, and compressors to improve energy efficiency and reduce failure rates.

Advantages

The 330102-00-20-10-02-00 vibration sensor offers several advantages for users:

-

Reliable Fault Detection: Capable of detecting early signs of mechanical issues such as imbalance, misalignment, or bearing wear.

-

High Accuracy: It offers precise vibration measurements, helping to identify and address issues before they lead to failure.

-

Durable Design: With an IP67 rating, it is dust-tight and water-resistant, making it suitable for harsh industrial environments.

-

Ease of Integration: The sensor features a 4-20 mA output, which is compatible with most control and monitoring systems.

-

Cost-Efficiency: Early detection of faults minimizes the risk of expensive unplanned maintenance or replacements.

-

Compact Size: Designed to fit in tight spaces, it is easy to install on a wide variety of machinery.

-

Low Power Consumption: The sensor operates on a 15-30 VDC power supply, making it energy-efficient for continuous monitoring.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330102-00-20-10-02-00 |

| Brand | Bently Nevada |

| Series | 3300 XL |

| Type | Vibration Sensor |

| Output Type | 4-20 mA |

| Measurement Range | ±100g to ±500g |

| Frequency Range | 10 Hz to 10 kHz |

| Power Supply | 15-30 VDC |

| Size (L x W x H) | 145 mm x 95 mm x 48 mm |

| Weight | 0.56 kg |

| Mounting Type | Integral Mounting |

| Protection Class | IP67 (Dust-tight and Water-resistant) |

Recommended Related Models from the 3300 XL Series

| Model | Specification |

|---|---|

| 330101-00-68-05-02-00 | Vibration Sensor, ±500g Measurement Range, 4-20 mA Output, 0.5 kg |

| 330106-00-02-03-00-00 | Vibration Sensor, Frequency Range: 5 Hz to 5 kHz, ±250g, 0.46 kg |

| 330102-00-10-10-01-00 | Vibration Sensor, ±500g Measurement Range, 4-20 mA Output, 0.48 kg |

| 330107-00-08-09-00-00 | Vibration Transducer, ±400g Measurement Range, 4-20 mA Output, 0.49 kg |

| 330109-00-09-11-00-00 | Vibration Sensor, ±1000g Measurement Range, 4-20 mA Output, 0.55 kg |

Recommended Popular Models from Bently Nevada

| Model | Specification |

|---|---|

| 330500-00-03-08-00-00 | Vibration Sensor, Frequency Range: 0.1 Hz to 2 kHz, ±75g Measurement Range, 0.43 kg |

| 330110-00-06-10-00-00 | Vibration Sensor, ±400g Measurement Range, Frequency Range: 5 Hz to 10 kHz, 0.47 kg |

| 330102-00-10-10-01-01 | Vibration Sensor, ±300g Measurement Range, Frequency Range: 5 Hz to 5 kHz, 0.48 kg |

| 330101-00-68-05-02-00 | Vibration Transducer, ±500g Measurement Range, Frequency Range: 10 Hz to 10 kHz, 0.5 kg |

| 330104-00-02-06-00-00 | Vibration Sensor, ±200g Measurement Range, Frequency Range: 1 Hz to 10 kHz, 0.45 kg |

Frequently Asked Questions (FAQ)

Q1: What is the operating temperature range of the 330102-00-20-10-02-00?

A1: The 330102-00-20-10-02-00 operates within a temperature range of -40°C to +85°C, ensuring reliable performance in various industrial environments.

Q2: Is the 330102-00-20-10-02-00 sensor suitable for use in hazardous locations?

A2: This sensor is not certified for hazardous locations, but it is designed to withstand harsh environments such as high vibrations, moisture, and dust.

Q3: How is the sensor mounted on machinery?

A3: The 330102-00-20-10-02-00 sensor is mounted using an integral mounting system, making it easy to install on rotating machinery.

Q4: What types of faults can the sensor detect?

A4: The sensor detects mechanical faults like imbalance, misalignment, bearing wear, and other vibration abnormalities in rotating equipment.

Q5: How accurate is the vibration measurement provided by this sensor?

A5: The 330102-00-20-10-02-00 provides high accuracy in vibration measurement, with a frequency range of 10 Hz to 10 kHz and a measurement range of ±100g to ±500g.

Q6: What kind of output does this sensor provide?

A6: The 330102-00-20-10-02-00 provides a 4-20 mA output, making it compatible with most industrial control and monitoring systems.

Q7: Can this sensor be used for continuous monitoring of rotating machinery?

A7: Yes, the 330102-00-20-10-02-00 is ideal for continuous vibration monitoring of rotating machinery, helping detect issues before they lead to failure.

Q8: How does the 330102-00-20-10-02-00 compare with other sensors in terms of durability?

A8: The 330102-00-20-10-02-00 is designed for use in demanding industrial environments, with an IP67 rating for dust and water resistance, making it highly durable.

Q9: Can the sensor be easily integrated into existing monitoring systems?

A9: Yes, the 330102-00-20-10-02-00 can be easily integrated with existing monitoring systems through its standard 4-20 mA output.

Q10: What is the expected lifespan of the 330102-00-20-10-02-00?

A10: The 330102-00-20-10-02-00 is built to last for many years when properly maintained, providing long-term, reliable performance in industrial applications.