ProductPRODUCT

Featured products

Contact Us

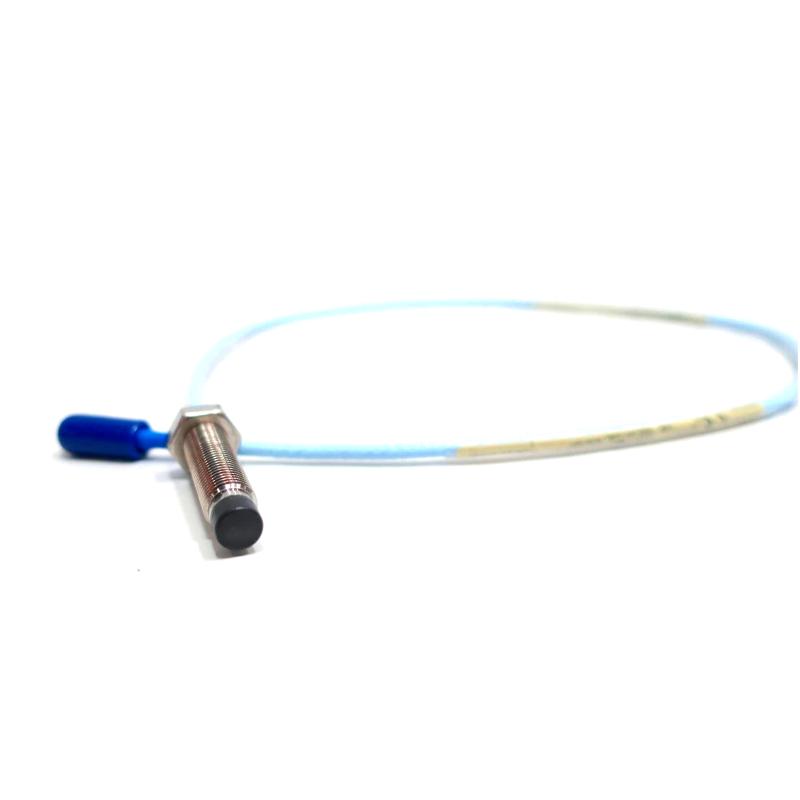

- Bently Nevada

- 330101-00-68-05-02-00

- 3300 XL 8 mm Proximity Probe

- USA

- 127 x 100 x 40 mm

- 0.5kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 77

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Overview: Bently Nevada 330101-00-68-05-02-00

The Bently Nevada 330101-00-68-05-02-00 is a state-of-the-art machinery monitoring system designed for high-precision monitoring of industrial equipment. Bently Nevada is a leader in providing condition monitoring solutions that help industries improve reliability, performance, and safety of their rotating machinery. The 330101-00-68-05-02-00 is one of the advanced sensors used for monitoring vibration, temperature, and other critical parameters that affect the operational efficiency of machines.

Product Features:

-

Model: 330101-00-68-05-02-00

-

Brand: Bently Nevada

-

Series: 3300 XL

-

Function: Vibration Monitoring and Condition Monitoring for industrial machines

-

Type: Vibration Transducer / Sensor

-

Application: Used primarily in power plants, petrochemical industries, and other large manufacturing units for machinery health monitoring

-

Mounting: Typically mounted on rotating machinery like motors, pumps, turbines, compressors, and fans to detect issues such as imbalance, misalignment, bearing wear, and others.

Applications:

-

Power Generation: To ensure the reliability of turbines and generators.

-

Oil and Gas: To monitor compressors, pumps, and turbines to avoid breakdowns and costly repairs.

-

Manufacturing: In heavy-duty manufacturing plants, Bently Nevada products help monitor critical machinery to prevent downtime.

-

Mining: For monitoring mining equipment that operates under harsh conditions.

-

Transportation and HVAC: To monitor motors and fans for efficient operation.

Product Advantages:

-

Real-time Monitoring: Provides continuous and real-time data of machine condition.

-

Enhanced Predictive Maintenance: Helps predict potential failures before they occur, reducing unplanned downtime.

-

Increased Operational Efficiency: By monitoring key machine parameters, it optimizes machine performance.

-

Scalability: Can be integrated into large systems and networks to provide a comprehensive view of equipment health.

-

Durability: Built to withstand harsh industrial environments.

-

User-friendly Interface: Easy to install and operate, with a simple setup process.

-

Reliability: Bently Nevada is known for delivering reliable and high-performance products that ensure optimal machine health.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 330101-00-68-05-02-00 |

| Brand | Bently Nevada |

| Series | 3300 XL |

| Type | Vibration Transducer / Sensor |

| Output Type | 4-20 mA Output |

| Measurement Range | ±50g to ±500g |

| Frequency Range | 10 Hz to 10 kHz |

| Sensor Type | Accelerometer |

| Power Supply | 15-30 VDC |

| Mounting Type | Integral Mounting |

| Size (L x W x H) | 127 x 100 x 40 mm |

| Weight | 0.5 kg |

Recommended Related Models from the 3300 XL Series

| Model | Specification |

|---|---|

| 330103-00-01-05-00-00 | Vibration Sensor, Frequency Range: 10 Hz to 10 kHz, ±100g Measurement Range, 4-20 mA Output, 0.4 kg |

| 330104-00-02-06-00-00 | Vibration Sensor, Frequency Range: 1 Hz to 10 kHz, ±200g Measurement Range, 4-20 mA Output, 0.45 kg |

| 330105-00-03-07-00-00 | Vibration Transducer, Frequency Range: 5 Hz to 5 kHz, ±50g Measurement Range, 4-20 mA Output, 0.42 kg |

| 330107-00-08-09-00-00 | Vibration Transducer, Frequency Range: 10 Hz to 5 kHz, ±300g Measurement Range, 4-20 mA Output, 0.48 kg |

| 330108-00-04-10-00-00 | Vibration Transducer, Frequency Range: 1 Hz to 10 kHz, ±150g Measurement Range, 4-20 mA Output, 0.46 kg |

Recommended Popular Models from Bently Nevada

| Model | Specification |

|---|---|

| 330101-00-10-10-00-00 | Vibration Transducer, Frequency Range: 5 Hz to 5 kHz, ±100g Measurement Range, 4-20 mA Output, 0.45 kg |

| 330106-00-02-03-00-00 | Vibration Sensor, Frequency Range: 10 Hz to 10 kHz, ±250g Measurement Range, 4-20 mA Output, 0.5 kg |

| 330110-00-06-01-00-00 | Vibration Transducer, Frequency Range: 1 Hz to 10 kHz, ±50g Measurement Range, 4-20 mA Output, 0.4 kg |

| 330201-00-01-05-00-00 | Vibration Sensor, Frequency Range: 10 Hz to 5 kHz, ±200g Measurement Range, 4-20 mA Output, 0.48 kg |

| 330500-00-03-08-00-00 | Vibration Transducer, Frequency Range: 0.1 Hz to 2 kHz, ±75g Measurement Range, 4-20 mA Output, 0.43 kg |

Frequently Asked Questions (FAQ)

Q1: What is the operating temperature range of the Bently Nevada 330101-00-68-05-02-00?

A1: The operating temperature range of the Bently Nevada 330101-00-68-05-02-00 is from -40°C to +85°C.

Q2: Can the 330101-00-68-05-02-00 be used in outdoor environments?

A2: Yes, it is suitable for harsh industrial environments, including outdoor applications, provided it is properly housed in a protective enclosure.

Q3: How do I install the Bently Nevada 330101-00-68-05-02-00?

A3: Installation involves mounting the sensor on the machine’s casing or bearing housing using the integral mounting feature and connecting the 4-20 mA output to a compatible monitoring system.

Q4: What types of machines can the 330101-00-68-05-02-00 monitor?

A4: It is designed to monitor rotating machinery such as turbines, pumps, compressors, and fans.

Q5: How accurate is the vibration measurement?

A5: The 330101-00-68-05-02-00 offers high precision with a vibration measurement range of ±50g to ±500g.

Q6: Is this product compatible with other Bently Nevada systems?

A6: Yes, it is fully compatible with other Bently Nevada monitoring systems and can be integrated into a broader condition monitoring network.

Q7: What is the power supply requirement for this product?

A7: The product operates with a 15-30 VDC power supply.

Q8: How do I troubleshoot if the sensor is not functioning properly?

A8: If the sensor is not functioning, check the wiring connections, power supply, and ensure it is installed correctly. Consult the user manual for troubleshooting steps.

Q9: Can the 330101-00-68-05-02-00 be used to detect misalignment?

A9: Yes, this sensor is capable of detecting various fault conditions such as imbalance, misalignment, and bearing wear.

Q10: What is the typical lifespan of the 330101-00-68-05-02-00?

A10: The sensor is designed for long-term durability and can operate for many years in industrial settings, provided it is maintained properly.