ProductPRODUCT

Featured products

Contact Us

- Bently Nevada

- 3500/91 161216-01

- Communication Gateway Module

- USA

- 241.3 mm × 24.4 mm × 241.8 mm

- 0.79kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 103

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product: Bently Nevada 3500/91 161216‑01

Parameter Table / Technical Specifications

| Parameter | Value |

|---|---|

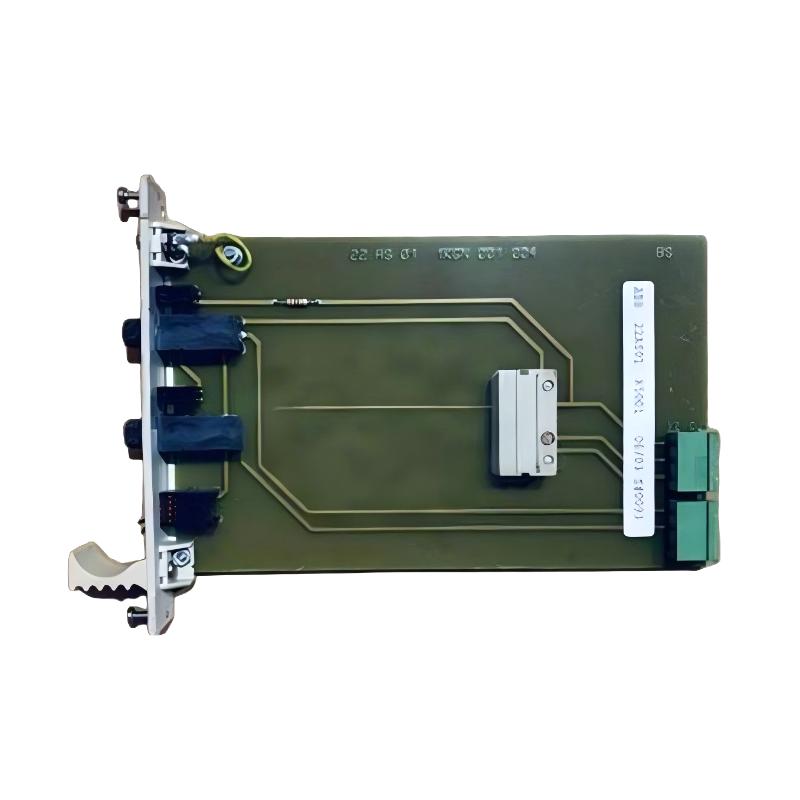

| Model Number | 3500/91 161216‑01 |

| Product Type | EGD Communication Gateway Module |

| Series | 3500 Machinery Protection System |

| Brand | Bently Nevada |

| Function | Provides Ethernet Global Data (EGD) gateway / communication of rack‑monitored values/status |

| Protocols Supported | EGD (version 2.01), Ethernet UDP/IP; Ethernet via IEEE 802.3 (10BASE‑T, 100BASE‑TX) |

| Connection Ports / I/O Module | RJ‑45 for twisted‑pair Ethernet; optional fiber MT‑RJ for 100BASE‑FX I/O module |

| Power Consumption | ≈ 7.4 watts (typical) |

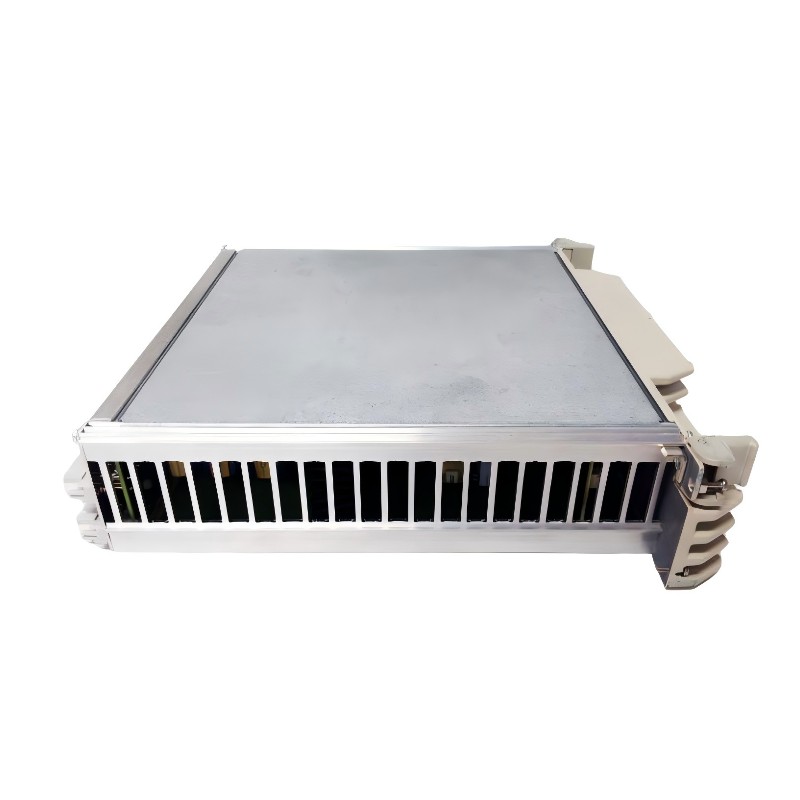

| Rack / Module Height / Slot | Main module occupies one full‑height front panel slot; I/O module occupies corresponding rear slot |

| Operating Temperature Range | −30 °C to +65 °C |

| Storage Temperature Range | −40 °C to +85 °C |

| Relative Humidity | Up to 95%, non‑condensing |

| Physical Dimensions (Main Module) | Height 241.3 mm × Width 24.4 mm × Depth 241.8 mm |

| Weight (Main Module) | ≈ 0.79 kg (1.75 lbs) |

| Physical Dimensions (I/O Module) | Height 241.3 mm × Width 24.4 mm × Depth 99.1 mm |

| Weight (I/O Module) | ≈ 0.39 kg (0.85 lbs) |

| Environmental Protection | Standard industrial protections; relative humidity, temperature, etc. |

| Compatibility / Requirements | Requires compatible 3500 rack, matching firmware version in 3500/22M TDI; only one 3500/91 per rack allowed |

Product Introduction

The 3500/91 161216‑01 is a communication gateway device in the 3500 Machinery Protection System. Its main job is to take all the monitored data from modules in a 3500 rack (vibration, temperature, speed, displacement, alarm statuses, etc.) and publish/produce that data via Ethernet using the EGD (Ethernet Global Data) protocol or UDP/IP, so that higher‑level control systems (DCS, SCADA, controllers) can receive real‑time machine health & status information. It also supports some “consumer” functionality: it can receive certain control/signaling (e.g. group reset, alarm inhibit, etc.) from external controllers. It is made to be tough, operate in industrial environments, be rack mounted, and integrate seamlessly with the rest of the 3500 Series.

Product Applications

Typical applications include, but are not limited to:

-

Power generation plants (steam turbines, gas turbines, generators) for real‑time monitoring and integration to control systems.

-

Oil & gas installations (compression stations, pumps, offshore platform rotating equipment) where reliable data sharing with control systems is required.

-

Refineries, petrochemicals, where condition monitoring, alarm status, trending need to be fed into central systems.

-

Manufacturing / heavy industry with critical rotating machinery.

-

Any facility using the 3500 Protection System that needs to communicate rack status and monitored values out to other systems in real time via Ethernet.

Product Advantages

Some of the advantages / strengths of the 3500/91 161216‑01 include:

-

Real‑time Ethernet communication: Using EGD and UDP/IP over standard Ethernet provides fast and predictable data exchange with low latency.

-

Standard interfaces and protocols: Ethernet, common standards (IEEE 802.3), which helps with integration, maintenance, compatibility.

-

Modular rack design: Fits the 3500 rack system; module and I/O separated so easier installation, replacement, etc.

-

Efficient power consumption: Around 7.4 W typical, which is reasonable for its functionality.

-

Compact physical footprint: The module is slim in width (24.4 mm front panel), so rack space is used efficiently.

-

Reliability in industrial / harsh conditions: The temperature/humidity ranges, and built‑in protections, ensure stable performance under typical industrial stresses.

-

Bidirectional functionality: Not just outputting data but also can accept control or status commands (e.g. group reset, alarm inhibit etc.), which helps central control integration.

-

Allows only one per rack: Ensures system stability, avoids conflicts or ambiguity in data paths.

Brand and Series

-

Brand: Bently Nevada

-

Series: 3500 Machinery Protection System

The 3500 Series is a well‑known, mature, modular machinery protection and condition monitoring system. It uses racks populated by various monitor modules (vibration, displacement, speed, temperature, etc.), relay modules, power modules, transient data interface modules (TDI), and communication gateway modules like the 3500/91.

Related and Alternative Models

Below are tables with:

-

Five other models in the same series or closely related (i.e. other 3500 communication / monitor / gateway / interface modules).

-

Five popular models of the same brand (Bently Nevada / related) that are frequently used, with their parameters.

Table A: Same Series / Related Models

| Model | Function / Role | Protocols / Key Features | Dimensions (Main or Relevant mm) | Weight (kg) |

|---|---|---|---|---|

| 3500/90 125728‑01 | Communication Gateway Module (earlier / alternate type) | Supports Modbus, Ethernet / serial to transfer 3500 rack data/status | ≈ 241.3 × 24.4 × 241.3 mm | ≈ 0.56 kg |

| 3500/42M | Vibration / displacement monitor (Proximitor® / seismic) | Measures proximitor, velocity, with internal signal conditioning | 241.3 × 24.4 × 241.3 mm | ≈ 0.58 kg |

| 3500/22M | Transient Data Interface (TDI) | Collects waveform / transient data, supplies interface for config software | 241.3 × 24.4 × 241.3 mm | ≈ 0.57 kg |

| 3500/53 133388‑01 | Overspeed / speed relay module | Detects overspeed, provides relay outputs | 241.3 × 24.4 × 241.3 mm | ≈ 0.56 kg |

| 3500/32M | Relay module | Provides relay outputs from alarm status of monitor modules | 241.3 × 24.4 × 241.3 mm | ≈ 0.58 kg |

Table B: Popular Models from Same Brand (Bently Nevada)

| Model | Function / Role | Protocols / Key Features | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3300 XL Proximitor | Proximity sensor / displacement transducer | Measures shaft displacement with high precision | Approx. 71 × 25.4 × 25.4 mm | ~0.12 kg |

| 1900/65A | Vibration monitor (portable / permanent) | Acceleration, velocity etc.; used in portable diagnostics | ~144 × 72 × 118 mm | ~0.85 kg |

| 3500/25 | Keyphasor Module | Generates tachometer / keyphasor signals from shaft speed | 241.3 × 24.4 × 241.3 mm | ~0.54 kg |

| 2300 Monitor | Compact dual‑channel or multi‑channel vibration monitor | Ethernet / Modbus / dual channel vibration | ~134 × 144 × 118 mm | ~1.2 kg |

| 3500/60 | Temperature Monitor Module | Monitors multiple thermal inputs (RTDs / thermocouples) | 241.3 × 24.4 × 241.3 mm | ~0.50‑0.60 kg (depending) |

FAQs (Q&A)

Here are 10 frequently asked questions, in a straightforward style:

Q1: What does the “161216‑01” refer to?

A1: It is the part number / revision number of the I/O portion of the module; the 3500/91 consists of a main module plus an I/O module (161216‑01 is the Ethernet I/O module for 10BASE‑T/100BASE‑TX or similar).

Q2: Can I install more than one 3500/91 Gateway in the same 3500 rack?

A2: No, only one 3500/91 EGD gateway module is allowed per rack. Using more than one can lead to conflicts in data exchange and system configuration.

Q3: What firmware or software versions are required for the module to operate correctly?

A3: The firmware version of the 3500/22M TDI must be at or above a certain version (often 1.20 or higher), and the 3500 rack configuration software likewise must be updated to a version that supports the 3500/91 gateway.

Q4: What types of external systems can be integrated with this module?

A4: DCS, SCADA, PLCs, controllers compatible with EGD (Ethernet Global Data) protocol, or systems that accept UDP/IP or standard Ethernet, to receive monitored values, alarm status, etc.

Q5: Does the module support fiber optic communication?

A5: Yes, via the I/O module variant supporting 100BASE‑FX (fiber optic) using MT‑RJ connectors if that I/O module is chosen.

Q6: What happens to system alarms or trip signals – can they be triggered via the gateway?

A6: The gateway is mainly for data export / import of control commands like alarming or group reset, alarm inhibit, etc., but it does not itself replace the monitor or relay modules that perform the actual trip or shutdown function.

Q7: What are the environmental limits for operation?

A7: Operating temp approx −30 °C to +65 °C; storage −40 °C to +85 °C; relative humidity up to ~95% non‑condensing.

Q8: What power supply does it need?

A8: It draws its power from the 3500 rack backplane; typical power consumption ~7.4 watts. No external power supply needed beyond the rack’s normal supply.

Q9: How is data latency / response time for external controllers?

A9: It supports Ethernet at 10/100 Mbps, EGD protocol, which is designed for time‑sensitive exchanges; performance depends on network configuration, but it is built to provide response times suitable for controller / alarm tasks.

Q10: What physical size / weight is this module; how difficult is it to install?

A10: The main module is about 241.3 × 24.4 × 241.8 mm, weighing ~0.79 kg; the I/O module is 241.3 × 24.4 × 99.1 mm weighing ~0.39 kg. Installation involves inserting into the 3500 rack slots (main front slot, I/O rear slot), connecting Ethernet/fiber as required, and configuring via the rack configuration software. It is not very heavy, but attention to rack alignment and connectors is needed.