ProductPRODUCT

Featured products

Contact Us

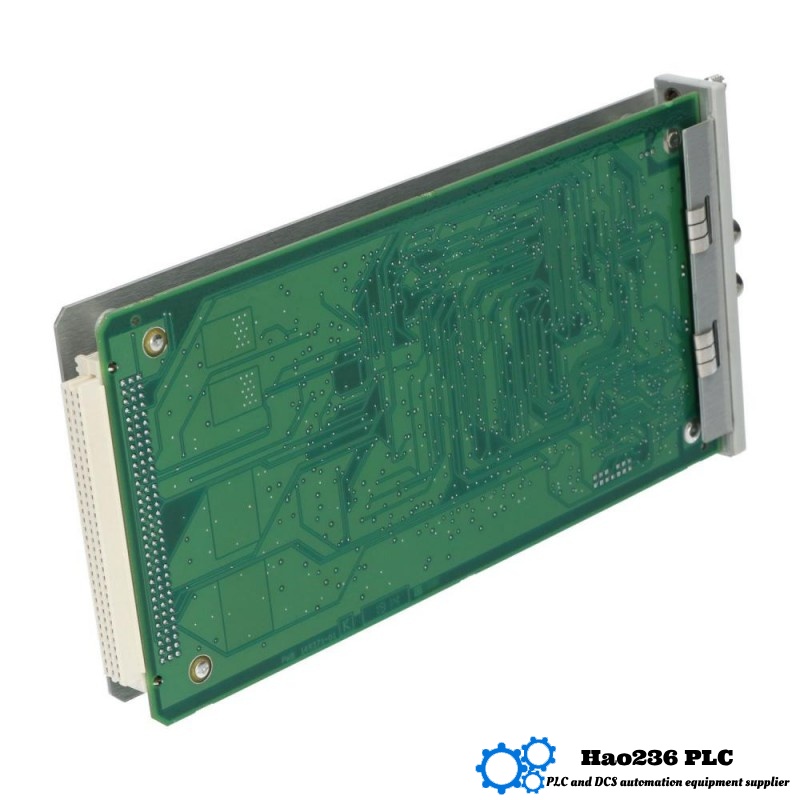

- Bently Nevada

- 3500/25 125792-01+149369-01

- Enhanced Keyphasor Module

- USA

- 267 mm x 160 mm x 55 mm

- 1.2kg

- Xiamen, China

- New & In Stock

- T/T, PayPal, Western Union

- 1 Year

- 1-3 Working Days

- DHL, UPS, TNT, FedEx and EMS.

- 24-Hour Service

- COO

- 67

Our advantage

Global Logistics

We have a 10-year logistics and express cooperation agreement, so our products can be shipped to any place in the world.

Brand new and original

Our products are imported in bulk from the place of origin. Because of the cooperative relationship, our products are all original and 100% new.

24-hour service

We provide 7*24 hours service to our customers. We will be there whenever you need us.

Price advantage

All our products are priced very favorably because we have our own warehouse and supply.

| Company Information | |||

| [email protected] | |||

| Mobile | +8615980777398 | ||

| +8615980777398 | |||

| 15980777398 |

Product Overview: Bently Nevada 3500/25 125792-01 + 149369-01

Product Introduction:

The Bently Nevada 3500/25 model is part of the 3500 series, which provides highly accurate machinery protection and condition monitoring solutions. Designed for use in industrial environments, the 3500/25 offers superior performance in vibration monitoring, machinery protection, and diagnostic data collection. With the 3500 series, users can monitor critical machinery components such as bearings, shafts, and other vital rotating equipment.

The product comes with advanced features and rugged design, allowing it to function effectively in extreme conditions such as high temperatures, vibrations, and harsh environments. This specific model combines the monitoring capabilities of both hardware and software, making it an indispensable tool for predictive maintenance and operational efficiency.

Product Features:

-

Real-time vibration monitoring with advanced diagnostics.

-

Compatibility with other machinery monitoring components of the Bently Nevada 3500 series.

-

Wide operating temperature range, enabling use in industrial environments.

-

User-friendly interface, simplifying configuration and maintenance.

-

Continuous performance monitoring to prevent failures and optimize machinery uptime.

Product Specifications:

| Specification | Details |

|---|---|

| Model Number | 3500/25 125792-01 + 149369-01 |

| Type | Vibration Monitoring System |

| Dimensions (L x W x H) | 267 mm x 160 mm x 55 mm |

| Weight | 1.2 kg |

| Input Voltage | 24V DC |

| Measurement Range | 0 – 2000 Hz |

| Temperature Range | -20°C to 60°C |

| Environmental Protection | IP65 |

| Display | LED Indicators |

| Mounting Options | Panel, DIN Rail |

| Communication Protocols | Ethernet, Modbus, Profibus |

Product Application:

The Bently Nevada 3500/25 is typically used in industries where rotating machinery plays a crucial role in the operation. It is ideal for monitoring critical equipment such as:

-

Gas turbines

-

Compressors

-

Electric motors

-

Pumps

-

Fans

The system helps in detecting early signs of failure, reducing unplanned downtimes, and extending the life cycle of machinery. It also supports predictive maintenance programs, allowing companies to schedule repairs before failures occur.

Advantages:

-

Highly Accurate Monitoring: Offers precise vibration analysis, which helps prevent machine breakdowns.

-

Robust Build Quality: Designed to withstand challenging industrial environments.

-

Real-time Alerts: Provides immediate notifications to avoid unexpected downtime.

-

Modular and Scalable: Easily integrated into existing systems, with flexibility for future expansions.

-

Easy Maintenance: Low-maintenance system that minimizes operational costs over time.

Brand:

-

Brand: Bently Nevada

-

Brand Overview: Bently Nevada is a renowned manufacturer specializing in machinery monitoring and protection systems. It is recognized for producing reliable products that optimize the performance and safety of industrial equipment.

Series:

-

Series: Bently Nevada 3500 Series

Recommended Products in the Same Series or Related Models

| Model Number | Key Features | Weight (kg) | Dimensions (L x W x H) |

|---|---|---|---|

| 3500/32 | Vibration and temperature monitoring system | 1.1 | 250 mm x 150 mm x 50 mm |

| 3500/53 | Monitoring of industrial compressors | 1.3 | 280 mm x 160 mm x 55 mm |

| 3500/90 | Vibration monitoring for high-speed machinery | 1.0 | 240 mm x 140 mm x 45 mm |

| 3500/22 | Advanced machinery protection system | 1.2 | 270 mm x 155 mm x 50 mm |

| 3500/25 (Alternative) | Dual-channel vibration monitoring system | 1.2 | 267 mm x 160 mm x 55 mm |

Recommended Popular Models from the Same Brand

| Model Number | Key Features | Weight (kg) | Dimensions (L x W x H) |

|---|---|---|---|

| 3500/42M | Vibration sensor for rotating machinery | 1.0 | 250 mm x 155 mm x 50 mm |

| 3500/20 | 3-Channel vibration system for large turbines | 1.5 | 280 mm x 160 mm x 60 mm |

| 3500/95 | Monitoring system for high-efficiency motors | 1.3 | 260 mm x 150 mm x 55 mm |

| 3500/35 | Advanced diagnostic unit for gas turbines | 1.4 | 270 mm x 155 mm x 55 mm |

| 3500/77 | Protection system for power generation equipment | 1.6 | 275 mm x 160 mm x 60 mm |

FAQ (10 Questions and Answers)

Q1: What is the purpose of the Bently Nevada 3500/25 model?

A1: The Bently Nevada 3500/25 is designed for vibration monitoring and machinery protection. It helps prevent failure by continuously tracking vibration levels and other critical parameters.

Q2: How does the 3500/25 help with predictive maintenance?

A2: By continuously monitoring the condition of machinery, the system can detect early signs of wear or failure, allowing for maintenance to be scheduled before a failure occurs.

Q3: What types of machinery can be monitored using the 3500/25?

A3: The 3500/25 is suitable for monitoring rotating machinery such as turbines, compressors, electric motors, and pumps.

Q4: What is the temperature range for the 3500/25?

A4: The 3500/25 operates within a temperature range of -20°C to 60°C, making it suitable for a variety of industrial environments.

Q5: Can the Bently Nevada 3500/25 communicate with other monitoring systems?

A5: Yes, the 3500/25 is compatible with various communication protocols, including Ethernet, Modbus, and Profibus.

Q6: Is the Bently Nevada 3500/25 system easy to install?

A6: Yes, the system has a user-friendly interface and can be mounted on a panel or DIN rail, making installation quick and easy.

Q7: How does the Bently Nevada 3500/25 prevent unexpected downtimes?

A7: By providing real-time vibration monitoring and diagnostic data, the 3500/25 enables operators to take corrective actions before problems escalate into costly downtime.

Q8: What is the warranty period for the 3500/25 model?

A8: The warranty period typically lasts for 12 months from the date of purchase, although this can vary depending on the region and supplier.

Q9: Does the system have any built-in diagnostic capabilities?

A9: Yes, the 3500/25 includes advanced diagnostic features that analyze the condition of machinery components and provide detailed reports.

Q10: What are the mounting options for the Bently Nevada 3500/25?

A10: The system can be mounted on both panels and DIN rails, offering flexibility for different installation scenarios.